Void Technology

Gravity Drive Insert

Our insert uses principles of elasticity to generate more consistent putts. Our patent pending design uses an exotic thermoplastic called polyethersulfone (PES) which we bond to specially milled 303 stainless steel.

The thickness of the PES increases towards either edge of the insert. This increased thickness generates more kinetic energy on impact which compensates for distance normally lost on heel or toe strikes.

In the test below, a golf ball was dropped out of a device positioned 15 inches above various test surfaces. Each photo shows 10 tests overlaid so the average rebound height is visible. Label "0" represents a steel face and labels 1-4 represent increasing thicknesses of PES (the drop height was adjusted and constant in every test). A max rebound height gain of 1/2'' was achieved with the thickest material.

These results mean we can add energy to areas of the putter face that need it and create consistent roll distances across a wider surface area.

How does this help?

When you miss the center of the club during a putt the ball won't travel as far. Hitting on the heel or toe moves the ball away from the center of mass and can cause the putter head to twist at impact. This will result in the ball coming off the face slower and not landing as far as intended. The "sweet spot" on a traditional putter is only about the size of a quarter, easy to miss.

Using our patent pending "Gravity Drive" technology, we've increased the sweet-spot area across the entire insert. Adding energy towards the heel and toe of the putter face generates consistent roll distances, even on miss-hits.

What does this mean on the green?

Our insert is tuned to remove inconsistencies when putting from 15-20 feet. Many birdies and par-saves are made or missed within this range.

In our testing, the drop height of 15 inches produces a ball speed of 2.7m/s. When we reference the USGA Stimpmeter for greens, golf balls travel 6.55 ft per 1m/s of ball speed on a fast green. This is the velocity needed to sink a put of about 15-20 feet. From this distance we found that a strike 1/2 inch off center will result in a putt that ends up 5-10 inches short on average when using a standard putter.

When we compare the steel control test to the PES test, we observe an energy conservation that makes up for this lost roll distance. In the steel control test, the ball had a return velocity of roughly 2.5m/s. The ball would have rolled 16.3 feet (196 inches) -- In the thickest PES test, the ball had a return velocity of 2.6m/s. The ball rolls out to 17 feet (204 inches), a gain of 8 inches.

By precision milling the PES to gradually gain thickness towards the heel and toe, we're able to create uniform roll distances across the entire striking area.

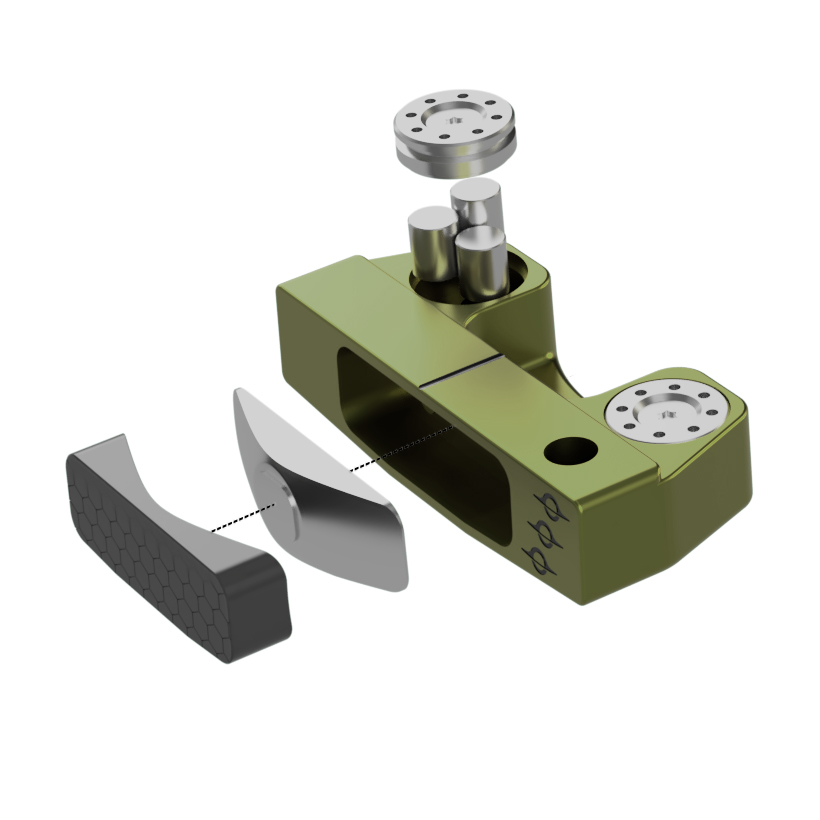

Maximum MOI

Our clubs contain up to 170 grams of tungsten assembled in a machine milled aluminum chassis. MOI (moment of inertia) is a measurement of an objects resistance to twisting. When the ball is hit off-center, the club tries to twist in your hands. This reduces accuracy and roll distance. Adding weight to the heel and toe increase a clubs resistance to twisting negating the negative effects of a miss-hit. Using lightweight billet aluminum has allowed us to position up to 50% of the putters weight to maximize MOI. Combine this with the Gravity Drive insert and you've got one of the most forgiving clubs on the market.

Our putters are proudly milled, hand finished, and assembled in San Diego, California USA.